Crystal Bonding- Haɗin Fasaha Na Lu'ulu'u Laser

Bayanin Samfura

Mahimmancin aikace-aikacen fasaha na haɗin gwiwa akan lu'ulu'u na laser ya ta'allaka ne a cikin: 1.Miniaturization da haɗin kai na na'urori / tsarin laser, irin su Nd: YAG / Cr: YAG bonding don samar da ƙananan Q-switched microchip lasers; 2. Inganta thermal kwanciyar hankali na Laser sanduna Performance, kamar YAG / Nd: YAG / YAG (wato, bonded tare da tsarki YAG don samar da abin da ake kira "karshen hula" a duka iyakar da Laser sanda) iya rage yawan zafin jiki Yunƙurin na karshen fuskar Nd: YAG sanda a lokacin da yake aiki, yafi amfani da Sol-state famfo high Laser famfo.

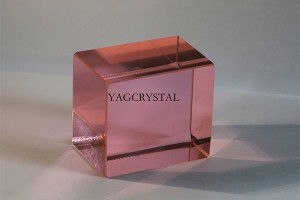

Babban kamfaninmu na yanzu manyan YAG jerin samfuran kristal sun haɗa da: Nd: YAG da Cr4+: YAG bonded rods, Nd: YAG bonded tare da tsarki YAG a duka iyakar, Yb: YAG da Cr4 +: YAG bonded sanduna, da dai sauransu .; diamita daga Φ3 ~ 15mm, tsawon (kauri) daga 0.5 ~ 120mm, kuma za'a iya sarrafa su cikin sassan murabba'ai ko zanen gado.

Bonded crystal samfuri ne wanda ya haɗu da kristal na Laser tare da ɗaya ko biyu tsarkakakku waɗanda ba su da kayan kwalliya iri ɗaya ta hanyar fasahar haɗin gwiwa don cimma daidaituwar haɗin gwiwa. Gwaje-gwaje sun nuna cewa haɗin lu'ulu'u na iya rage yawan zafin jiki na lu'ulu'u na Laser yadda ya kamata kuma ya rage tasirin tasirin ruwan tabarau na thermal wanda lalacewa ta ƙarshe ta haifar.

Siffofin

● Rage ruwan tabarau na zafi wanda ke haifar da nakasar fuska

● Inganta ingantaccen canjin haske-zuwa-haske

● Ƙara juriya ga ƙofa na lalata hoto

● Inganta ingancin fitarwa na Laser

● Rage girma

| Lalata | <λ/10@632.8nm |

| ingancin saman | 10/5 |

| Daidaituwa | <10 seconds |

| A tsaye | <5 mintuna |

| Chamfer | 0.1mm@45° |

| Rufi Layer | AR ko HR shafi |

| Ingancin gani | Matsakaicin tsaka-tsaki: ≤ 0.125/inch Tsangwama: ≤ 0.125/inch |